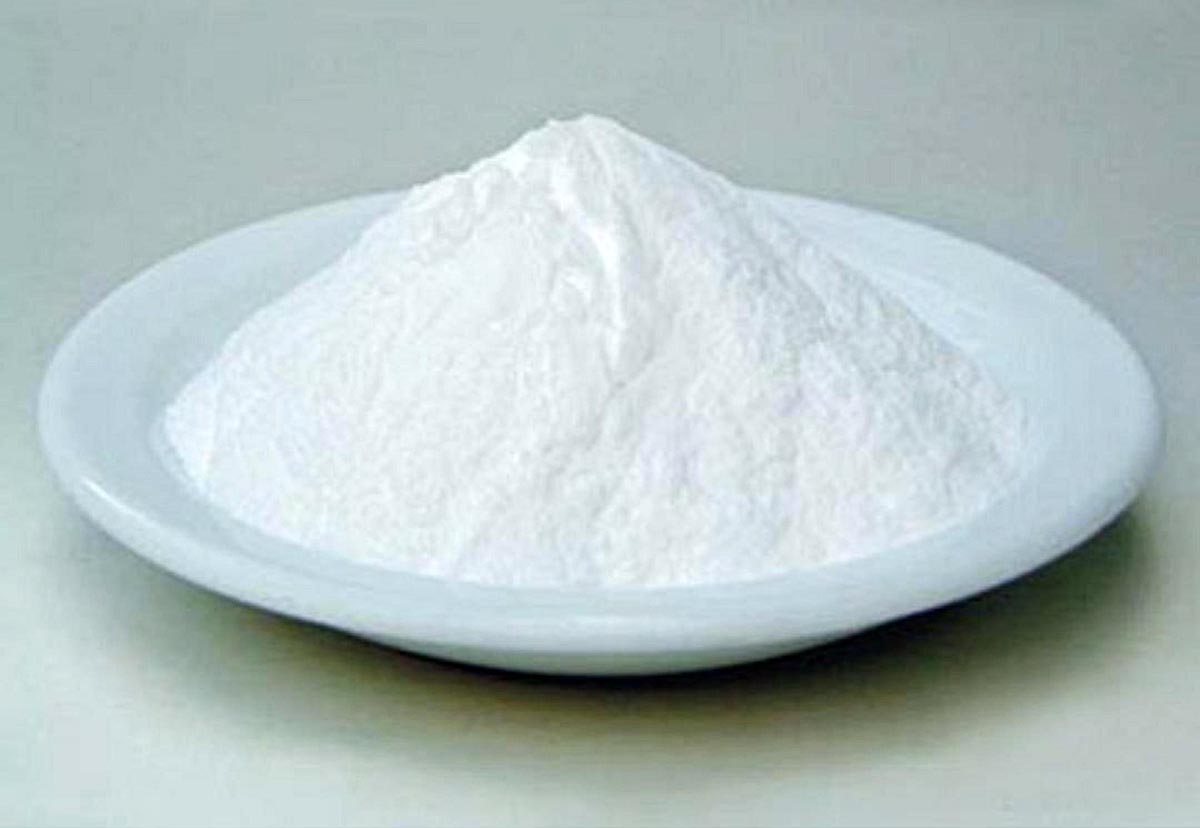

Process Equip has a proficiency in “Value added” or “Premium” grades of Precipitated silica. After an in-depth research we have developed many valuable product technologies for use in Tyre manufacturing, Food processing, Pharma & Detergent manufacturing etc.

Manufacturing Process:

Quite flexible Manufacturing process allowing wide variety of grades with a range of physical properties.

Acid is added to Sodium silicate (water glass solution) to form Amorphous Precipitated Silica. Resulting white precipitate is filtered, washed and dried in the Flash dryer.

Choice of agitation, duration of precipitation, the dosing rate of reactants, temperature, concentration and pH during reaction can result into various grades of Precipitated silica

Tyre Grade Silica

TYRE Grade Silica is preferred to over carbon black as a reinforcing filler in tire tread compounds. Natural rubbers (NR) with silica-filled tire treads have become known as green tires because of their significant gain in tire properties.

Recently, a value-added grade of silica called “Easily dispersible silica” has attracted researchers because of its superior functional properties. It is a benchmark for energy-saving and high-performance tires for passenger cars. It offers benefits for the automotive industry, allowing for increased productivity due to its impact on mixing and extrusion throughput and adding flexibility without compromising on rolling resistance, wear and grip.

Applications

– Tyre and Rubber industry

– Rice roller & Conveyor Belts

– Misc Rubber Goods

– Footwear

Need in Tyre industry:

- A major problem facing Tyre designers has traditionally been to solve the compromise between low rolling resistance, high wet grip and high wear resistance.

- Rolling resistance is the amount of energy a tyre absorbs as it revolves and deflects. The lower the rolling resistance the less fuel is required to propel the vehicle forward. Lowering the rolling resistance, however, commonly results in a reduction in wet grip performance, which of course is unacceptable.

- A major step in solving this problem can be achieved by the replacement of (part or all) carbon black by silica in the tyre’s tread compound. This has enabled manufacturers to produce tyres which provide improved wet grip properties, better winter performance and lower rolling resistance all at the same time.

Thickening Grade Silica

Thickening grade silica has a very strong thickening effect. Average particle size is < 5 μm. It provides optimum adjustment of rheology during processing.

IT ALSO HELPS IN :

- Reinforcement of silicone elastomers.

- Thickening of non-polar liquids in certain applications like, insulation against

- Temperature fluctuations.

- Free-flow of foodstuffs and industrial powders.

- High chemical purity.

- Excellent insulation properties, even at high temperatures.

- Conversion of liquids to powders, e.g. pharmaceuticals, cosmetics.

- Gelification of battery acids, rheology control of greases & lubricants.

Abbrasive Grade

ABBRASIVE GRADE silica helps maintaining rheology & improves mouth feel of the toothpaste. The transparency of high porous and high surface area of abrasive grade silica permits the development of transparent tooth paste.

Granules providing sensory feel, polishing effect, and aesthetic look in opaque / gel toothpaste. Skin Conditioning Agent. Provides cleaning action in plaque removal. Acts as polishing agent for cleaning action of tooth.

APPLICATIONS:

– Oral and Dental Care

– Personnel Care